Spiral wound gasket (SWG) consists of thin metal hoop and nonmetal filler material that are simultaneously wound. The metal hoop is pre-formed in V or W shaped profile, which allows the gasket to act as a spring between the flanges. The hoop also provides the basic structural element for the gasket while the nonmetal filler material seals the flange surfaces that are with small imperfections.

Depending on its excellent compression resilience, it is suitable for sealing spots where the alteration of temperature and pressure are frequent. It can be used as the static sealing element of pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc. It has been widely applied in the fields of petrochemical, mechanical manufactory, power station, metallurgy, shipbuilding, pharmaceutical, nuclear power station and navigation, etc

Styles:

| Type | Construction | Suitable flange | Hoop material | Filler material | Inner & outer ring material | Normal thickness | |

| Gasket | rings | ||||||

| A | Basic style | Tongue and groove | 304, 304L, 316, 316L, 321, 317L, Titanium, Nickel, Monel, Inconel, etc. | Graphite, PTFE, Asbestos, Non-asbestos, Ceramic, etc. | Carbon Steel, 304, 304L, 316, 316L, 321, 317L, Titanium, Nickel, Monel, Inconel, etc. | 3.2mm 4.5mm (0.175″) 6.4mm | 2mm 3mm (0.125″) 4mm |

| B |

With inner ring | Male and female | |||||

| C |

With outer ring | Raised face Flat face | |||||

| D |

With inner & outer ring | ||||||

| E |

For use with RTJ flanges | Ring-Type-Joint | |||||

| F |

With bar for heat exchanger | Heat exchanger |

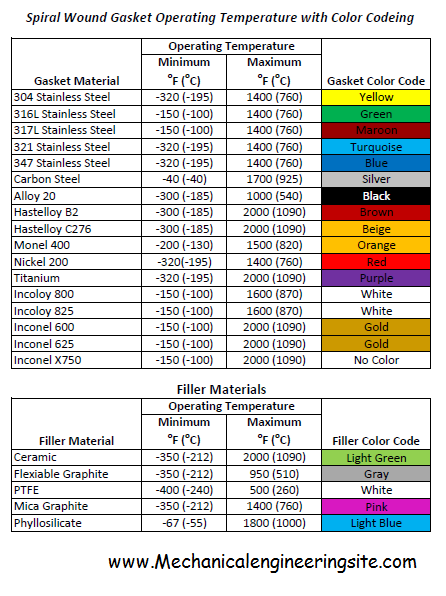

* Gaskets are color coded at the outside of the centering ring according to ASME B16.20 standards.

Specification:

| Filler material | Temperature | Pressure |

| Graphite | -240°C~+550°C in oxidizing media | 300bar in hot water, oil, etc. |

| -240°C~+800°C in non-oxidizing media | 200bar in vapor oil, gases, etc. | |

| Asbestos | -150°C~+450°C | 150bar |

| PTFE | -200°C~+250°C | 150bar |

Produced according to ASME, BS, JIS and DIN standards

Spiral

Wound Gasket Operating Temperature With Color Coding