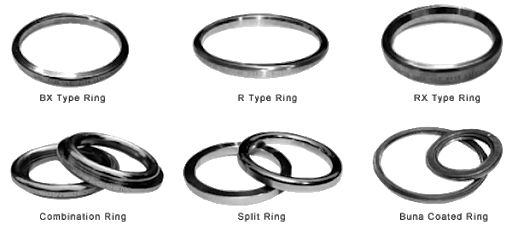

Ring joint gasket

Our ring joint gaskets are machined from solid metal in a variety of shapes with high quality numerical control machines. They are designed for high pressure, high temperature or highly corrosive applications by selecting the most suitable materials and shapes. Ring joint gaskets are forged and integral, non-welded.

R type oval ring joint gasket

Standard ring joint gaskets with oval cross section and designed for flanges with standard ring joint grooves.

R type octagonal ring joint gasket

Standard ring joint gaskets with octagonal cross section and designed for flanges with standard ring joint grooves. Interchangeable with oval section gasket on modern octagonal grooved flanges.

RX type ring joint gasket

An adaptation of the standard R type ring joint gasket and designed to fit the same groove design as R type. It is interchangeable with the standard R type gaskets.

BX type ring joint gasket

Designed for very high pressures. All BX gaskets incorporate a pressure balance hole to ensure equalization of pressure which may be trapped in the grooves. Only suited for API BX flanges and grooves.

Combination ring gasket

The gaskets consist of two different sizes having the same pitch circle diameter. Used for sealing ring type joint flanges where the mating flanges have different ring groove diameters or profiles. Available with either oval or octagonal facings.

Normal Materials:

| Metal material | Ring identification | Maximum hardness | Temperature |

| Soft iron* | D | 90 HB | -60°C~+500°C |

| Low carbon steel* | S | 120 HB | -40°C~+500°C |

| 5Cr1/2Mo | F5 | 130 HB | -40°C~+650°C |

| Stainless steel 304(L), 321 | S304(L), S321 | 160 HB | -250°C~+550°C |

| Stainless steel 316(L) | S316(L) | 160 HB | -100°C~+550°C |

| Stainless steel 347 | S347 | 160 HB | -250°C~+550°C |

* Gaskets made of soft iron or low carbon steel materials are normally applied with anticorrosive oil in final production.

Dimensions are in accordance with relevant standards (such as ASME B16.20, API 6A, etc.) to suit different flange designations (such as ASME B16.5, ASME B16.47 Series A, API 6B, API 6BX, etc.).