With the protection of PTFE bonding at the inner diameter, the PTFE bonded rubber gaskets could be suitable for use with most corrosive chemicals, and have long service life.

They have perfect sealing effect even at low bolt tightening force, and are ideal for plastic piping systems, plastic-lined metal systems, or metal systems.

The normal rubber materials for these gaskets are EPDM, FKM, etc.

PTFE bonded EPDM rubber gasket

EPDM rubber is ideal for outdoor applications because of its excellent resistance to heat, ozone, oxidants, UV rays, and severe weather conditions. It shows good resistance to many corrosive chemicals however does not have good oil resistance.

Suggested working temperature for gasket: -40°C~+90°C.

PTFE bonded FKM rubber gasket

FKM (Viton) rubber has excellent resistance to oil, flame, chemical corrosion, weathering and aging. It resists a wide variety of corrosive fluids at elevated temperatures while retaining their mechanical properties. The material is also with good tensile strength, resilience, and low compression set.

Suggested working temperature for gasket: -40°C~+120°C.

Typical Specifications:

| Color | Density | Tensile strength | Elongation at break | Hardness | |

| EPDM rubber | Black | 1.3g/cm3 | ≥10Mpa | ≥300% | 70±5 Shore A |

| FKM rubber | Black | 1.9g/cm3 | ≥12Mpa | ≥100% | 70±5 Shore A |

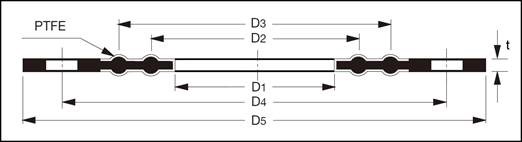

Thickness of bonded PTFE material: 0.3~0.4mm. The dimensions of the gaskets meet the requirements of ASME, DIN, or other standards. Special sizes and shapes are also available upon request